(1).jpg)

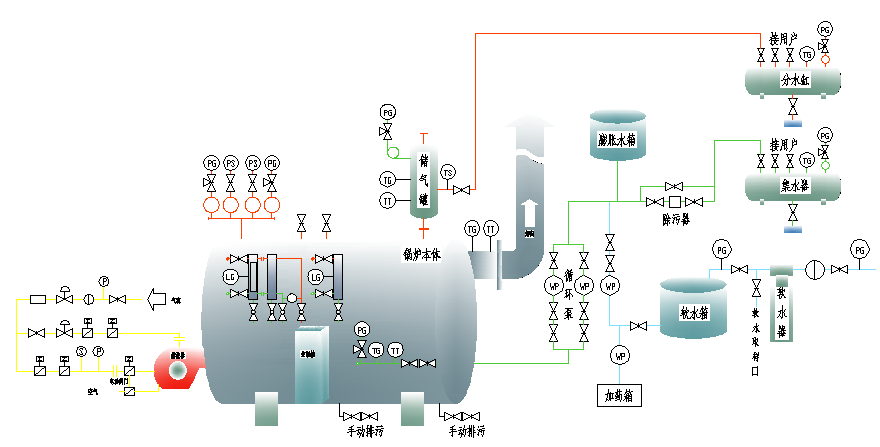

Steam and feed flow diagram

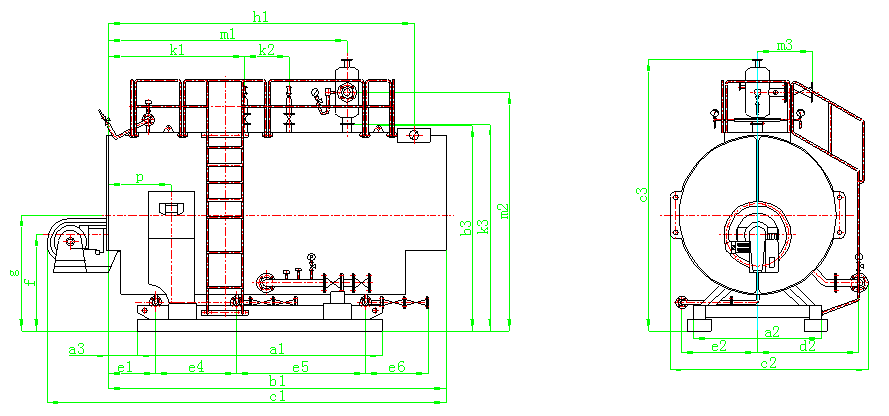

Size of S0.35-14MW hot water boiler

|

Length (mm) |

Base |

Transportation clearance |

Max overall dimension |

Water inlet |

Burner center |

Equipment center |

||||||||

|

Thermal power |

a1 |

a2 |

a3 |

b1 |

b2 |

b3 |

c1 |

c2 |

c3 |

d1 |

d2 |

d3 |

f |

g |

|

0.35MW |

2100 |

1100 |

250 |

3200 |

1370 |

1710 |

3430 |

1725 |

2335 |

2100 |

670 |

550 |

870 |

1000 |

|

0.7MW |

2600 |

1300 |

0 |

3283 |

1605 |

1960 |

3813 |

2085 |

2716 |

2488 |

850 |

560 |

905 |

1110 |

|

1.05MW |

3050 |

1300 |

0 |

3751 |

1735 |

2060 |

4291 |

2085 |

2816 |

3138 |

900 |

574 |

910 |

1160 |

|

1.4MW |

2740 |

1400 |

85 |

3750 |

1935 |

2215 |

4236 |

2060 |

3085 |

2870 |

1020 |

600 |

1000 |

1250 |

|

2.1MW |

3450 |

1600 |

425 |

4594 |

2145 |

2400 |

5308 |

2285 |

3340 |

3440 |

1050 |

650 |

1030 |

1350 |

|

2.8MW |

3450 |

1700 |

525 |

4880 |

2395 |

2612 |

5960 |

2515 |

3595 |

3869 |

1237 |

640 |

1136 |

1460 |

|

4.2MW |

3990 |

1850 |

525 |

5610 |

2550 |

2860 |

6950 |

2690 |

3949 |

4276 |

1295 |

660 |

1205 |

1580 |

|

5.6MW |

4650 |

1900 |

625 |

6196 |

2850 |

3094 |

3094 |

3025 |

4290 |

5150 |

1500 |

742 |

1215 |

1690 |

|

7.0MW |

5000 |

2000 |

625 |

6648 |

2940 |

3204 |

3204 |

3115 |

4400 |

5927 |

1450 |

475 |

1270 |

1750 |

|

8.4MW |

5700 |

1950 |

525 |

6900 |

3090 |

3510 |

3510 |

3240 |

4980 |

5916 |

1595 |

890 |

1460 |

2010 |

|

10.5MW |

5750 |

2500 |

525 |

7200 |

3525 |

3758 |

3758 |

3665 |

5170 |

6040 |

1650 |

625 |

1590 |

2100 |

|

14MW |

7150 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Length (mm) |

Manual sewage draining exit |

Relief valve connector |

Water outlet |

Chimney breast |

Control cabinet |

||||||||||

|

Thermal power |

e1 |

e2 |

e3 |

e4 |

e5 |

e6 |

k1 |

k2 |

k3 |

m1 |

m2 |

m3 |

h1 |

h2 |

p |

|

0.35MW |

2100 |

650 |

310 |

— |

— |

540 |

2050 |

— |

1820 |

1550 |

1985 |

470 |

2475 |

1700 |

850 |

|

0.7MW |

2180 |

800 |

300 |

— |

— |

600 |

2150 |

— |

2080 |

1650 |

2276 |

520 |

2550 |

1960 |

570 |

|

1.05MW |

2630 |

800 |

300 |

|

|

600 |

1750 |

|

2195 |

2200 |

2376 |

520 |

3000 |

2060 |

570 |

|

1.4MW |

2790 |

850 |

338 |

— |

— |

700 |

1750 |

— |

2335 |

2350 |

2650 |

560 |

3220 |

2215 |

620 |

|

2.1MW |

3600 |

900 |

360 |

— |

— |

700 |

1750 |

400 |

2415 |

2750 |

2870 |

750 |

4016 |

2400 |

1030 |

|

2.8MW |

2100 |

950 |

348 |

1710 |

— |

700 |

2190 |

400 |

2747 |

3090 |

3082 |

805 |

4245 |

2612 |

1140 |

|

4.2MW |

2860 |

1050 |

366 |

1590 |

— |

700 |

2450 |

500 |

2998 |

3650 |

3408 |

880 |

5005 |

2860 |

1190 |

|

5.6MW |

3270 |

1150 |

346 |

1800 |

— |

700 |

2950 |

500 |

3254 |

4100 |

3675 |

800 |

5575 |

3050 |

1700 |

|

7.0MW |

1450 |

1180 |

350 |

2100 |

2050 |

700 |

2700 |

600 |

3364 |

4000 |

3784 |

800 |

6025 |

3150 |

1700 |

|

8.4MW |

1950 |

1200 |

400 |

1950 |

1950 |

700 |

1690 |

600 |

3726 |

4300 |

4260 |

860 |

6350 |

3510 |

1940 |

|

10.5MW |

740 |

1600 |

350 |

2200 |

3150 |

700 |

2900 |

650 |

3918 |

4700 |

4448 |

860 |

6640 |

3758 |

1850 |

|

14MW |

2000 |

1800 |

330 |

2150 |

2450 |

700 |

3000 |

900 |

4370 |

5200 |

4850 |

860 |

7284 |

4165 |

2200 |

|

Note:The base elevation for 8.4MW,10.5MW and 14MW is 400mm. |

|||||||||||||||

※ Compact structure, attractive appearance.

※ Reasonable design of heating surface can effectively control resistance of smoke.

※ Appropriate control of exhaust gas temperature can ensure boiler efficiency.

※ Adopts unique detachable smoke box, thus it is easy for maintenance.

※ Special spring type explosion door and guarantee safety of boiler.

※ Adopts control system of programmable logic controller (PLC) and touch screen.

※ All-around online help, multilevel Chinese pop-up menu and breakdown maintenance manual.

※ All-around safety interlocking protection function can ensure the safe and efficient operation of boiler.

※ Sufficient PLC reserved port and modular expanding module can realize group control, remote control and building control.

Pre: Large-scale tower

Next: Energy-efficient horizontal steam boiler